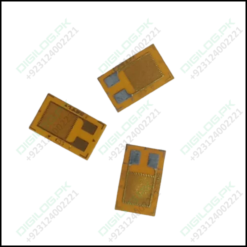

Bx120-10aa Foil Resistance Strain Gauge Weighing Sensor

₨ 250

Strain Gauge Sensor Foil Type Resistance Strain Gauge Pressure Gauge sensor.

A resistance strain gauge is a sensitive component that converts non-electricity into electricity. It is made of different materials and structures depending on the application. Resistance strain gauges come in a wide variety of applications with varying performance. In practical applications, in order to select a suitable strain gauge, various factors should be considered: First, the experimental or trial conditions should be considered, including: temperature, humidity, interference, patch area, and test piece materials.

Secondly, the condition of the test piece material should be considered, such as: material linear expansion coefficient, elastic modulus, structure and force distribution.

Selection principle of resistance strain gauge

1, the type of resistance strain gauge

According to the purpose of strain measurement, the material of the tested material and its stress state and measurement accuracy requirements, the type of strain gauge is selected. For example, the strain gauge is used for the sensitive component of the load cell at room temperature, and the zero drift is adopted, and the creep is small. Foil strain gauges.

2, the choice of sensitive grid and substrate material

According to the ambient temperature of the test piece, the test time and the maximum strain to be measured, and the measurement accuracy requirements, select the sensitive grid or the base material. For example, the strain measurement under normal temperature (negative 30 degrees – positive 80 degrees) is generally selected from Constantan. , Ivan material or phenolic substrate strain gauge; test at room temperature (within 150 degrees) using a polyimide substrate.

3, the choice of strain gauge resistance value

The strain gauge resistance value is selected according to the requirements of the test instrument corresponding to the resistance value and the measurement strain sensitivity, and the test conditions. For example, in the stress test, in order to match the resistance strain gauge, a 120 ohm strain gauge is generally used; for the sensor, in order to improve its stability or output sensitivity, high resistance (350 ohms, 1000 ohms or even higher) is often used. There are things to consider the signal to noise ratio, power consumption, and also use high resistance value strain gauges.

4, the choice of strain gauge size

According to the material and stress condition of the test piece, and the area where the strain gauge is allowed to be attached, the size of the strain gauge is selected. For example, if the stress distribution on the surface of the test piece is uniform or not changed and the adhesive surface is allowed to be large, the gate length should be selected. For large strain gauges, a 3mm strain gauge is recommended. Strain gauges with long grid lengths are easy to paste, wire, and have good heat dissipation. The smaller the size of the strain gauge, the higher the requirements for the pasting and the lower the heat dissipation. Therefore, it is advisable to select a strain gauge with a large gate length on the premise of ensuring the measurement accuracy and sufficient installation area.

Specifications & Features:

- Model: BX120-10AA

- Size:15mm*4.5mm

- Base materials: phenolic

- Sensitive gate material: high-quality constantan

- Specification: 4CM silver plated copper wire

- Suitable temperature: -30C~70C

- The sensitivity coefficient and dispersion: 2.1+/-2%

- The room temperature strain limit: more than 20000UM/M

- The fatigue life of >10000000

- The length of 4CM has good welding wire

Package Includes:

1x BX120 Sensor

Be the first to review “Bx120-10aa Foil Resistance Strain Gauge Weighing Sensor” Cancel reply

Related products

Industrial Components

1 Piece 2.2 Inch Flex Sensor In Pakistan Bend Detection Sensor

Arduino Modules Components

1kg Range Weighing Sensor Load Cell Sensor For Electronic Yzc-131

Industrial Components

10k Ntc Thermistor Thermal Resistor Temperature Sensor Ntc-mf52at

Consumer Electronics Online Shopping in Pakistan

100 Led 4 Surface Solar Light 3 Modes 120 Degree Pir Motion Sensor Light

Industrial Components

Reviews

There are no reviews yet.