Metal Gear Servo Motor MG90S 360

₨ 260

Out of stock

Features

Tiny and lightweight with high output power, this tiny servo I Helicopter, Quadcopter or Robot. durability.

The servo can rotate approximately 360 degrees (continue for clockwise & anticlockwise) and works just like the standard kinds but smaller. You can use any servo code, hardware or library to control these servos. Good for beginners who want to make stuff move without building a motor controller with feedback & gearbox, especially si (arms) and hardware.

Specifications:

- Weight: 13.4 g

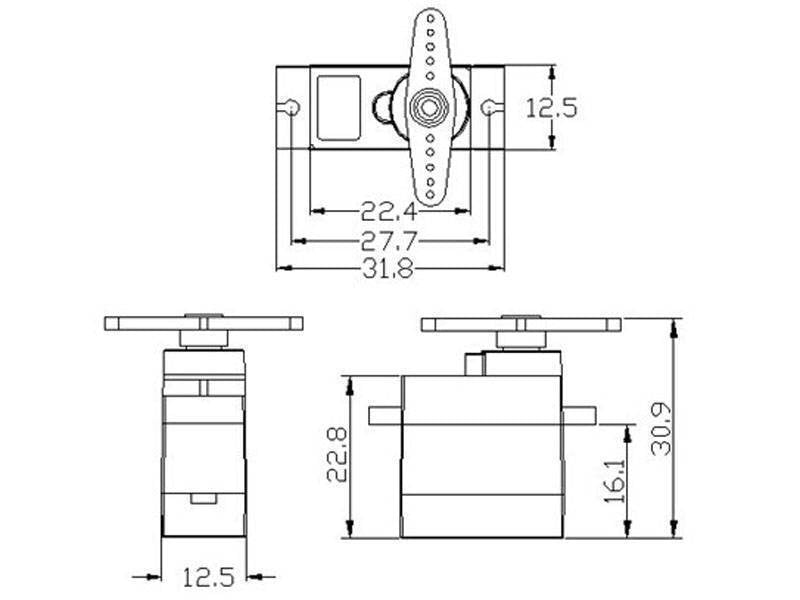

- Dimension: 22.5 x 12 x 35.5 mm approx.

- Stall torque: 1.8 kgf·cm (4.8V ) 2.2 kgf·cm (6 V)

- Operating speed: 0.1 s/60 degree (4.8 V), 0.08 s/60 degree (6 V)

- Operating voltage: 4.8 V – 6.0 V

- Dead band width: 5 µs

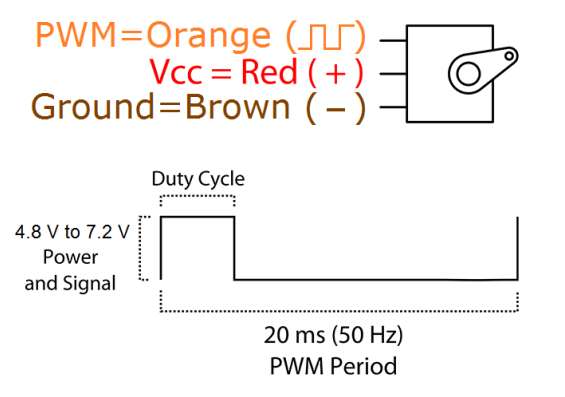

Wiring Diagram

Package includes

-

1x Towerpro MG90S 360 Degree Metal Gear With One Bearing Servo

-

Motor Connections

-

The built-in cable has a 3-pin female connector that is usually mated with a male header.

1×3 Female Connector specification:

-

Brown = Ground

-

Red = 5V

-

Orange = PWM Signal

Our evaluation results:

These servos are fairly strong little motors with metal gears.

The servo runs on 5V with a current draw about 10mA at idle and 120mA to 250mA when being commanded to move depending on how it is being operated. Current draw can get up to a maximum of 800mA under a stall condition, so be aware of that. One MG90S can typically be driven off the power pin of an Arduino when experimenting as long as you don’t stall it, but motors, in general, are electrically noisy and power hungry devices. It is always better to drive them directly off of a power supply rather than trying to power from the onboard Arduino regulator whenever possible

If you do decide to run it directly off the Arduino, you can help avoid most problems by running the power and ground from the Arduino over to a breadboard and then to the servo. By placing a fairly large electrolytic cap of around 470-1000uF across the power and ground on the breadboard, that will help to insulate the Arduino from some of the power surges of the motor.

The program below can be used to exercise a servo motor by using a potentiometer to set motor direction and to stop the motor if you position it to a value of about 90 as shown in the Serial Monitor window.

Servo Motor Micro MG90S Test Program

Exercise Servo motor

Use a potentiometer on pin A0 to command a servo attached to pin 9 to move to

a specific position. The Servo MIN_VALUE and MAX_VALUE can be adjusted to

avoid hitting the servo stops

Uses built-in Servo.h library

*/

#include “Servo.h”

#define SERVO_PIN 9 // Can use any PWM pin

#define POT_PIN A0 // Can use any analog pin

#define MIN_VALUE 0 // Minimum Servo value

#define MAX_VALUE 255 // Maximum Servo value

int value_pot = 0; // Current value of the potentiometer

int value_servo = 0; // Current servo position

int value_servo_old = 0; // Used to hold old servo value to look for change.

//===============================================================================

// Initialization

//===============================================================================

void setup()

{

servo.attach(SERVO_PIN); // assigns PWM pin to the servo object

Serial.begin (9600); // Set Serial Monitor window comm speed

}

//===============================================================================

// Main

//===============================================================================

void loop()

{

value_pot = analogRead(POT_PIN); // Reads value of the potentiometer. Return value = 0 to 1023

value_servo = map(value_pot, 0, 1023, MIN_VALUE, MAX_VALUE); // remap pot value to servo value

if (value_servo != value_servo_old) { // Only do something if there’s a change in the servo position

servo.write(value_servo); // Update servo position

Serial.print(“Pot Value: “); // Update Serial Monitor window with what’s going on

Serial.print(value_pot);

Serial.print(“tServo Value: “);

Serial.println(value_servo);

value_servo_old = value_servo;

delay(25); // give servo time to move

}

}

Before they are shipped, these servo motors are:

-

Inspected

-

Basic operation of servo motor verified

-

Repackaged for safe storage.

Technical Specifications

| Motor Model | MG90S | |

| Drive Type | Analog | |

| Degree Rotation | 360° continuous | |

| Operating Ratings | ||

| Voltage | 4.8-6VDC (5V Typical) | |

| Current (idle) | 10mA (typical) | |

| Current (typical during movement) | 120-250mA | |

| Current (stall) | 800mA (measured) | |

| Stall Torque | 2.2 kg-cm (per spec) | |

| Speed | 120 RPM | |

Dimensions |

||

| Cable Length | 24cm (9.5″) | |

| Motor Housing L x W x H | 23 x 12 x 26mm (0.9 x0 .5 x 1″) | |

| Motor Height (w/ shaft) | 32mm (1.26″) | |

| Motor Housing Width with Mounting Ears | 32mm (1.26″) |

Be the first to review “Metal Gear Servo Motor MG90S 360” Cancel reply

Related products

Commercial & Industrial

12v Low Rpm Incubator Egg Turner Motor In Pakistan Dc Gear Motor Dc Moving Motor

Commercial & Industrial

High Torque Gear Motor For Electric Bicycle Electric Cycle Electric Bike Price In Pakistan

Commercial & Industrial

360 Degree 9g Micro Servo Motor High Torque Dm-s0090md Digital 9g Servo Motor

Reviews

There are no reviews yet.